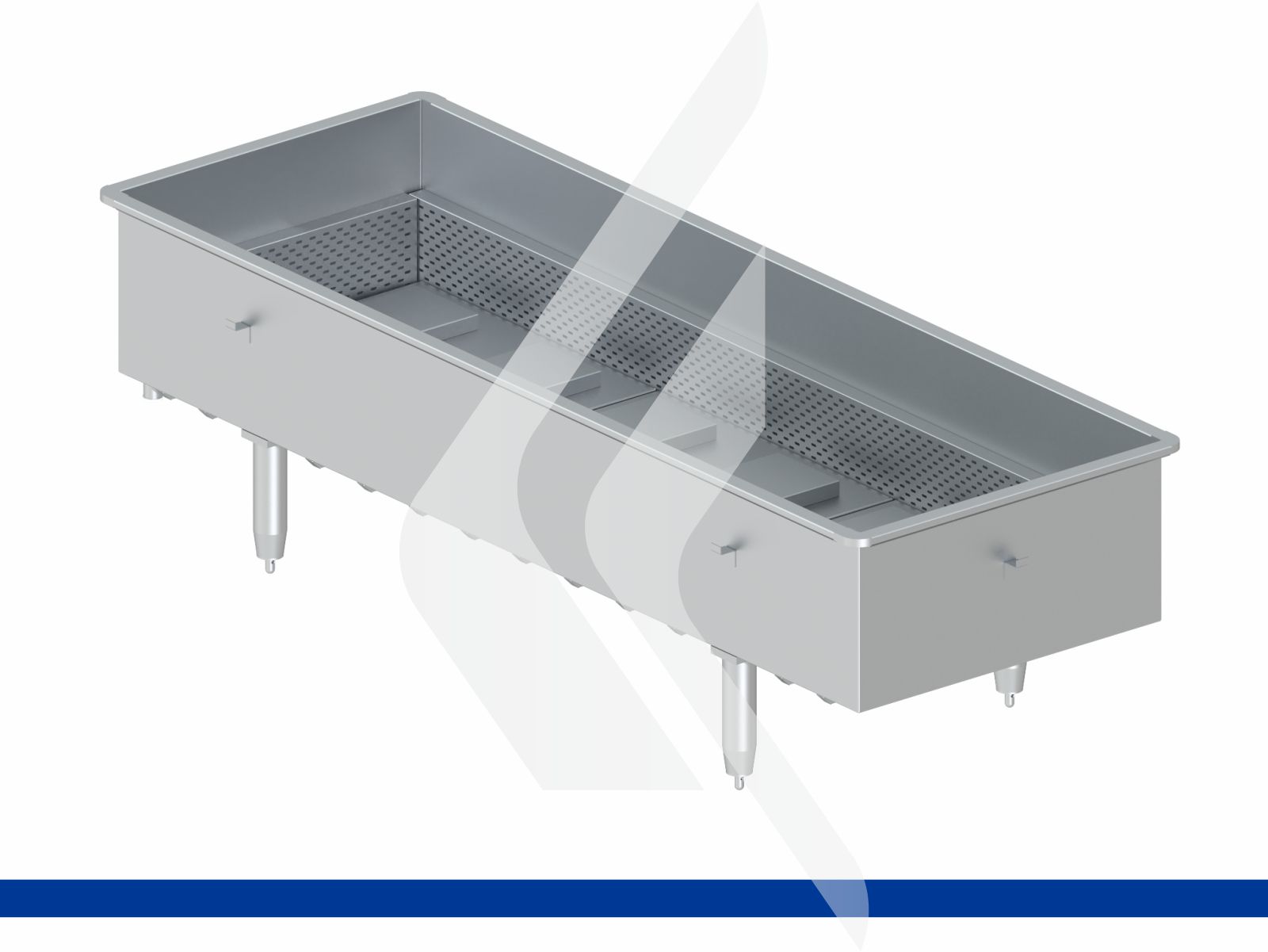

İstenilen özellikte hazırlanan süt, mayalama teknelerine alınarak mayalama işlemine tabi tutulur. Teleme beklemeye alınarak pıhtının sertleşmesi sağlanır. Bu aşamada peynir suyunu bırakır. Pıhtının kesim olgunluğu kontrol edilir. Pıhtı kesim olgunluğuna geldiğinde manuel olarak kesim işlemi yapılarak peynir küp şeker boyutunda kesilir. Pıhtı süzüldükten sonra manuel ağırlıklarla presleme işlemine tabi tutulur. Preslenen peynir mastar ve bıçaklarla istenilen ebatlarda kesilir. Salamura suyunda istenilen olgunluk değerine gelene kadar bekletildikten sonra ambalajlama işlemi yapılır.