White Cheese Production Lines

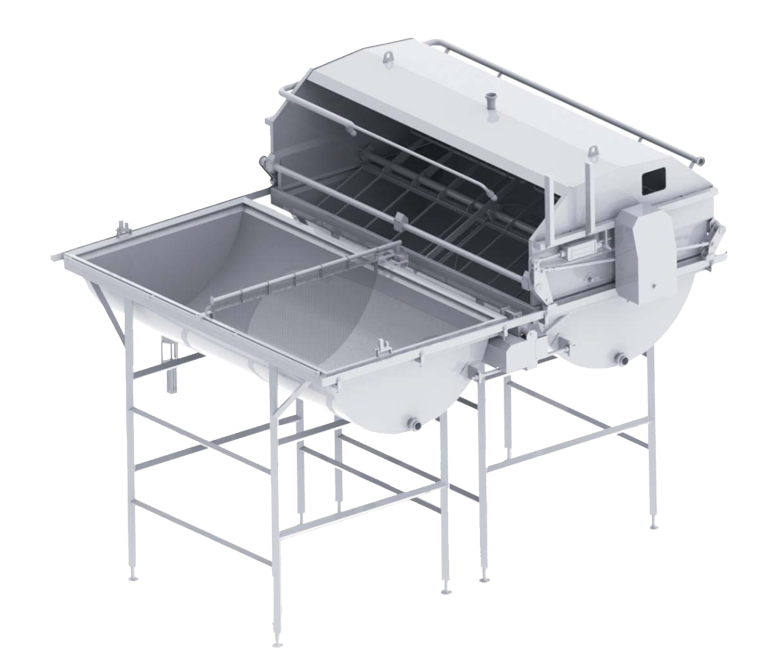

Auto Soft Cheese Vat

Working Principle

- It is an automatic vat in which the curd is prepared and mixed for the fermentation of milk for soft cheese groups.

- Pasteurized milk is filled into the fermentation vat.

- Yeast and culture are added to the milk and waited during maturation.

- The moving lid is placed on the vat and horizontal and vertical cutting operations are performed.

- Mixing process is done.

- The cheese cut into cubes is sent to the automatic molding machine together with the whey.

Technical Features

- Half round trough system.

- Made of AISI 304 and AISI 316 quality stainless steel.

- Common traveling pneumatic cover system is available for two boats.

- Automatic Horizontal and Vertical cutting blades.

- With the special knife system, it is ensured that the curd is cut without damaging and loss of yield is prevented.

- Automatic milk inlet and product discharge valve.

- PLC controlled.

- Washing automation with powerful CIP heads to ensure hygiene after each production.

- Prescription operation feature.

- Mixer speed is adjusted by inverter and reducer speed.

- Working platform is available.

System Advantages

- Automatic & Hygienic Production Advantage

- Optimum Production Area

- Standard Production Possibility

- Mass Production Advantage

- Automatic CIP Capability

- Cendere Cloth, Nylon Packaging Savings

- Detergent Savings

- Failure to Use the Washing Machine

- Electricity Savings

- Time Saving

- Water Saving

- Labor Savings

Application Fields

- Soft Cheese Groups

- White Cheese

- Village Cheese

- Camamber Cheese