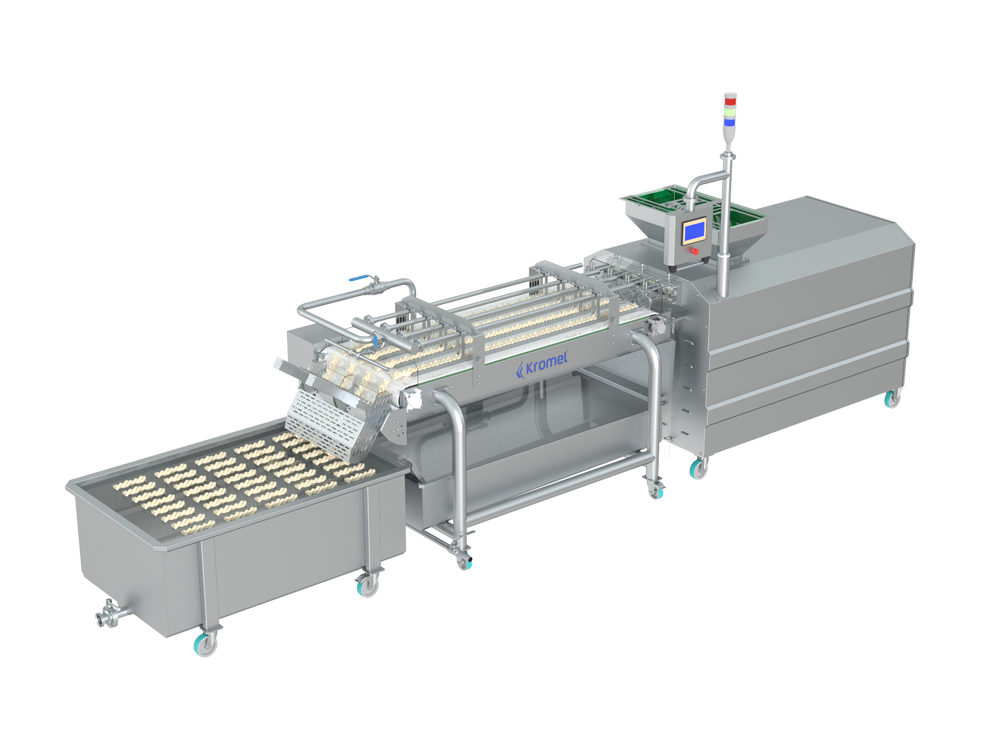

Hard and Semi-Hard Cheese Production Lines

Automatic Cheese Braided Machine

Working Principle

- The prepared dough is transferred to the product inlet hopper of the machine.

- The product is pushed forward with the help of the auger in the machine.

- The product gives its braid shape in the outlet mold in front of the machine with the help of a special gearbox.

- The knitted cheese is sent to the conveyor in front of the machine.

- The knitted cheese on the conveyor is cooled with cold water.

- With the help of a special pneumatic knife at the end of the conveyor, it is cut to the desired size.

- The cut knitted cheese falls into the cooling pool in front of the conveyor.

- It becomes ready for packaging according to the desired packaging shape

Technical Features

- Made of AISI 304 and AISI 316 quality materials

- PLC controlled

- Teflon or sandblasting

- Cooling heat exchanger

- Conveyor system suitable for special U-shaped product

- Pre-cooling system that preserves product form

- With Circulation Pump

- With speed control unit

- Ability to make products in different capacities

- Product collection unit with cooling pool

- Easy to use with wheels.

System Advantages

- Weight sensitivity

- Production at maximum hygiene level

- Fast product processing

- Ability to make standard products

- Low labor production capability

- Technological production feature

Application Fields

- Braided Cheese

Kapasite (Capacity) | Elektrik Sarfiyatı (Electricity Consumption) | Buhar Sarfiyatı (Steam Consumption) | Hava Sarfiyatı (Air Consumption) | Buzlu Su Sarfiyatı (Ice Water Consumption) |

|---|---|---|---|---|

| 150-200 KG/H | 3,45 Kw | 30 KG/H | 80 Lt/Dk. (6-8 Bar) | 3.000 Lt/H (+4°C) |