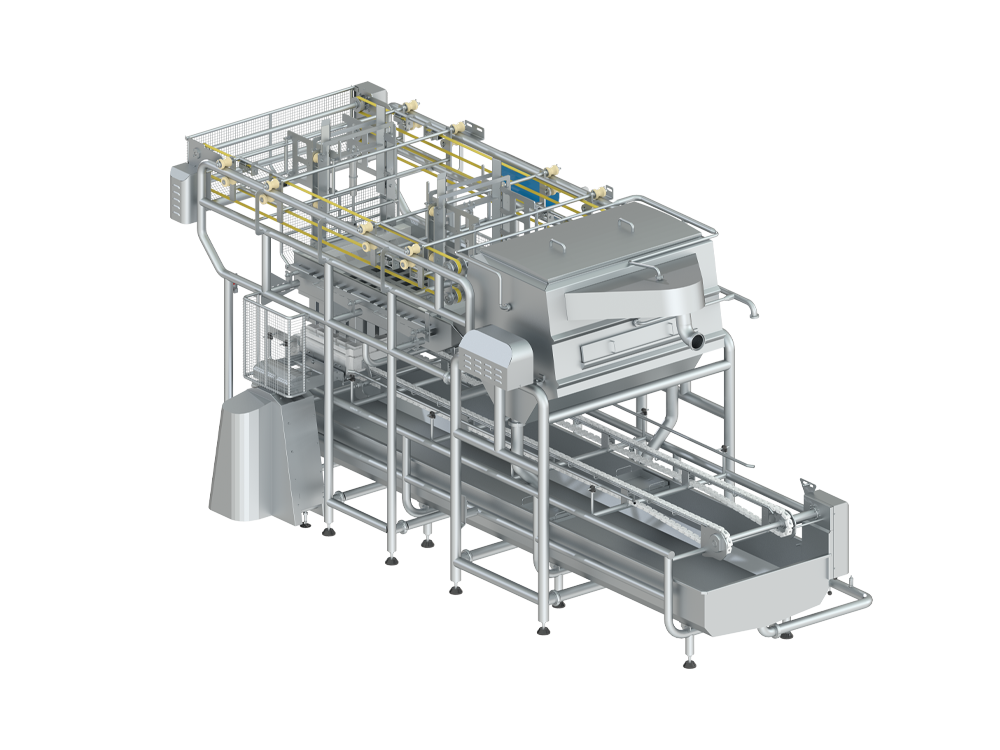

White Cheese Production Lines

Automatic Multi Mould Filling Machine

Working Principle

It is a machine where the curd and whey coming from the white cheese vats pass through a special perforated drum and the curd is automatically filled into multiple molds and the whey is automatically sent.

Technical Features

- Made of AISI 304 and AISI 316 quality stainless steel.

- Level controlled filling reservoir

- Automatic mold feeding conveyor

- Automatic shoveling system

- The curd on the rotating drum passes through a special drum sieve (0.2 - 0.5 mm slit spacing).

- The whey is collected in the drum bottom chamber.

- The whey is sent to the desired location by the P.A.S. pump under the lower chamber.

- Drum rotation speed can be controlled by inverter.

- PLC controlled

- There is a guide that can be changed according to the desired cheese shape.

- Automatic CIP feature is available.

System Advantages

- Automatic & Hygienic Production Advantage

- Easy to use Feature

- Standard Production Possibility

- Precise Weighting Feature

- Fast Production Advantage

- Automatic CIP Capability

- Labor Savings

Application Fields

- Soft Cheese Groups

- White Cheese

- Village Cheese

- Camamber Cheese