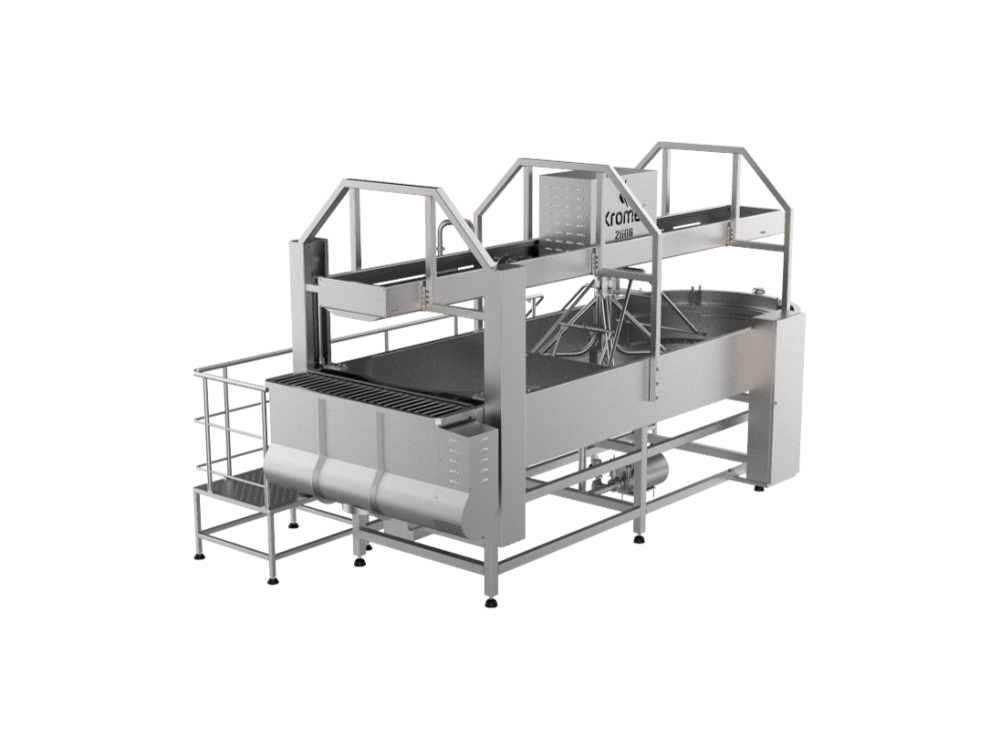

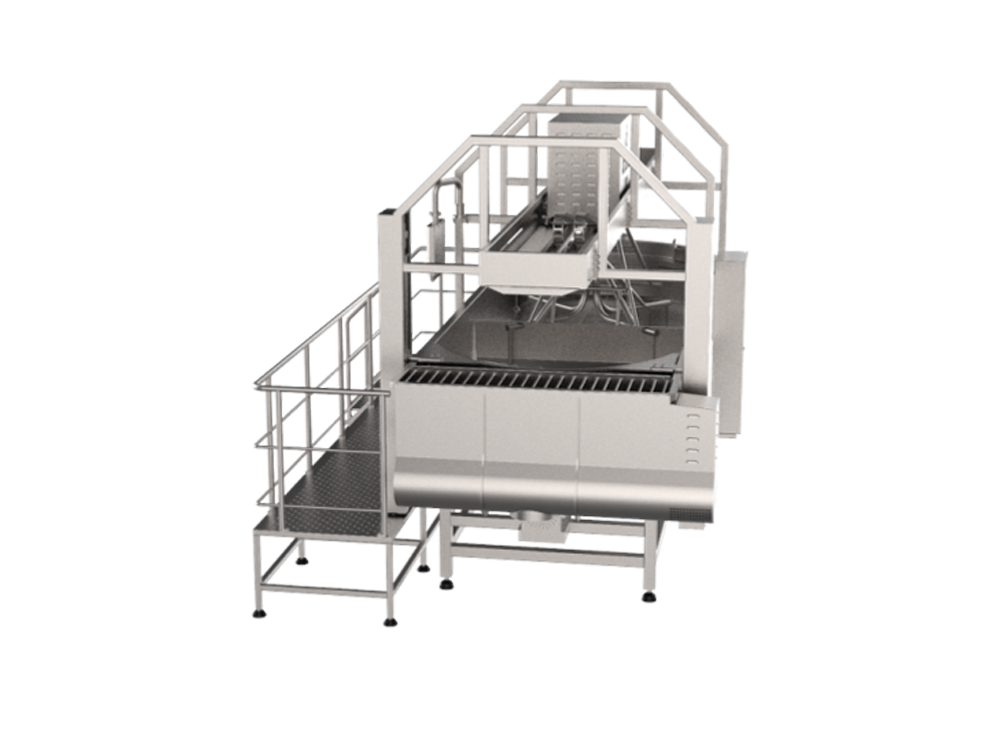

Hard and Semi-Hard Cheese Production Lines

Cheddaring Vat

Working Principle

- The mixture of curd and whey in the fermentation tank is transferred to the cheddaring vat either by pump or natural flow.

- The whey is discharged through a special perforated middle outlet strainer in the vat.

- The curd is mixed until it reaches the desired dry matter content and pH value.

- After mixing, a special pushing mechanism is installed to move the product forward.

- During unloading, the front cover is opened, the unloading paddle lowers, and the curd is dispensed onto the conveyor in front at a controlled rate.

- The lower screw then transports the product to the dry Steam cooking machine or hot water cooking machine.

Technical Features

- Completely made of AISI 304 stainless steel

- PLC control system

- Detachable mixers

- Removable bottom sieves

- Pneumatic front cover

- Pneumatic curd handling shovel

- Pneumatic end product push paddle

- Horizontal conveyor screw system

- Vertical conveyor auger system

- With safety switch

Application Fields

- Hard, Semi-hard Cheese Groups

- Cheddar Cheese

- Cheddar Cheese

- Mozzarella Cheese

System Advantages

- Removable straining plates suitable for cleaning and inspection.

- Fully supported trough bottom for complete draining.

- Special transportation system that allows the product to be carried forward.

- Special mixing mechanism preventing the curd from sticking.