Hard and Semi-Hard Cheese Production Lines

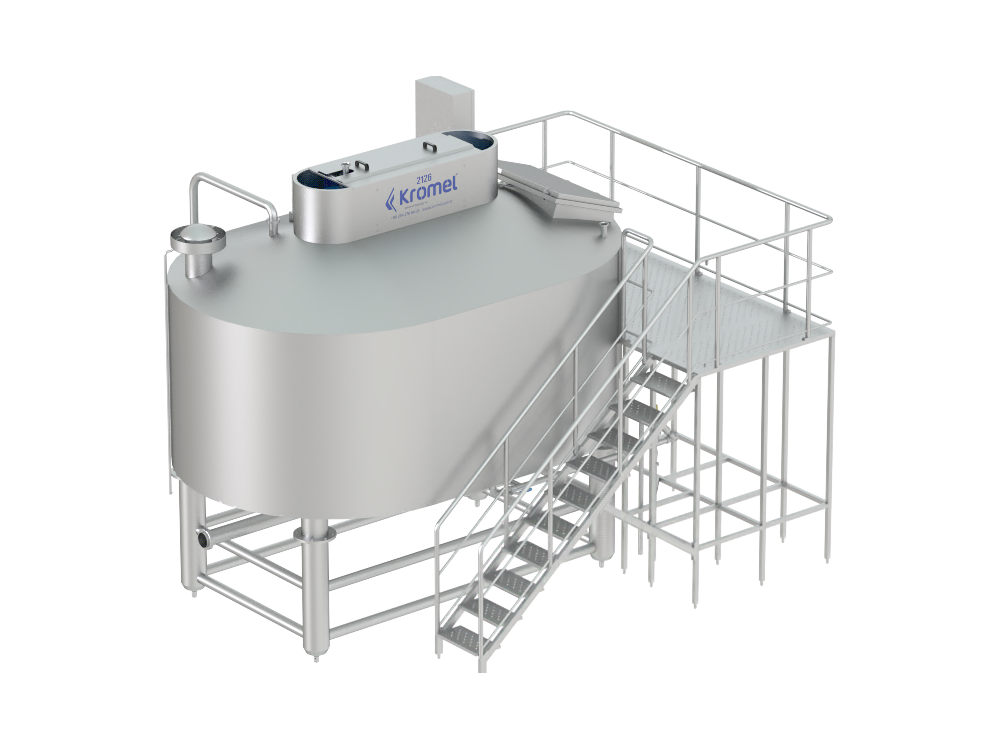

Cheese Vat

Working Principle

- Pasteurized milk is filled into the process tank and mixed.

- Yeast is added to the milk, the mixer is stopped and waited for the maturation period.

- The clot is heated by steam circulation between the Dimple Plate or wall.

- The clot matures into curd.

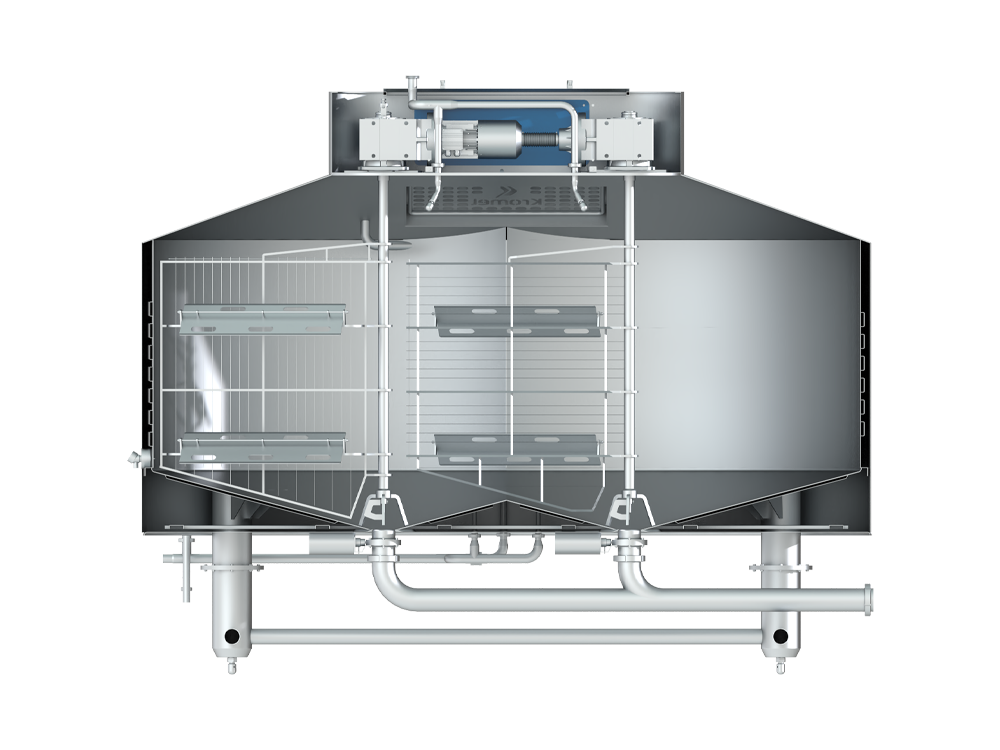

- The curd is cut with a special knife and mixer system.

- The agitator is started again and the product is heated until the desired pH value is reached.

- When the desired pH value is reached, the product is discharged from the tank.

Technical Features

- Eight type models Tank with horizontal and vertical special cutting blades.

- The special knife system ensures that the curd is cut without damage and prevents loss of efficiency.

- It has a stainless steel control panel; offers ergonomic ease of use with optional PLC automation control.

- Washing automation with powerful CIP heads that can provide hygiene after each production.

- Tank bottom outlet has a conical system and provides ease of emptying without damaging the curd.

- The special perforation in the process tank ensures that the cheese bottom water is drained at a certain rate and the process time is shortened.

- Prescription operation feature.

- Reducer speed is adjusted with frequency regulating inverter.

- Heating and insulation jacket.

- The temperature of the product in the tank can be seen digitally with the digital temperature indicator.

- There is a special mixer system for proper and homogeneous mixing.

System Advantages

- Even cutting of the curd due to the 8-shaped internal structure of the tank.

- High efficiency with minimal oil leakage.

- Cutting with a special knife system capable of horizontal and vertical cutting and mixing for homogeneous mixing.

- Suitable for cleaning with CIP system.

Application Fields

- Hard, Semi-hard Cheese

- Cheddar Cheese

- Mozzarella Cheese

- Gauda Cheese

- Edam Cheese

- Cedar Cheese

- Curd Production