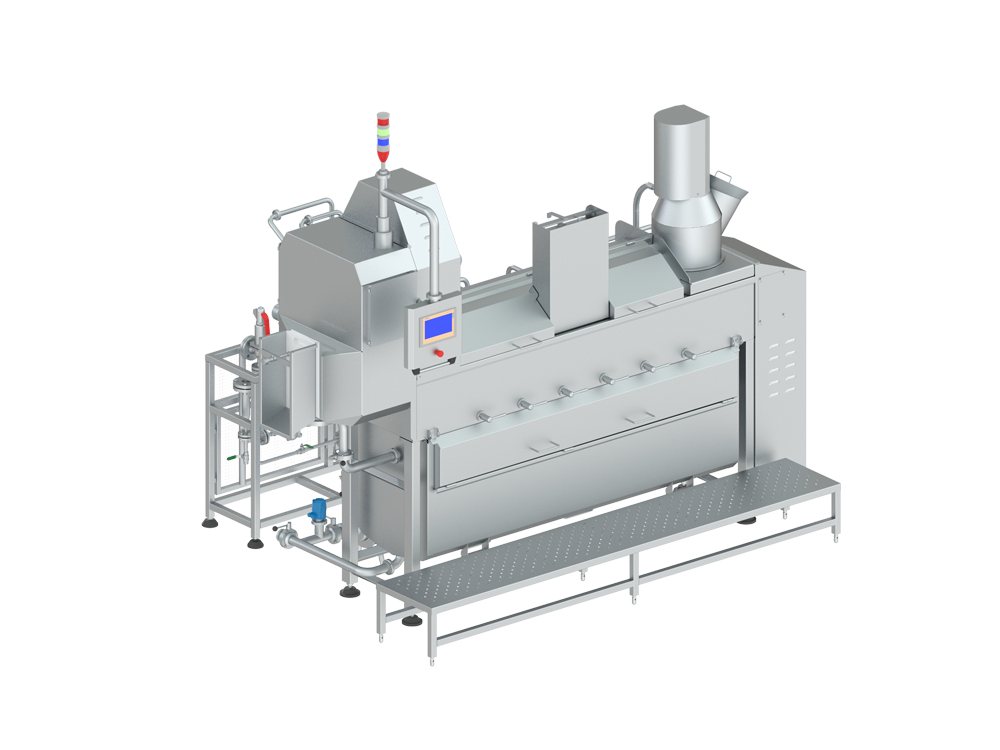

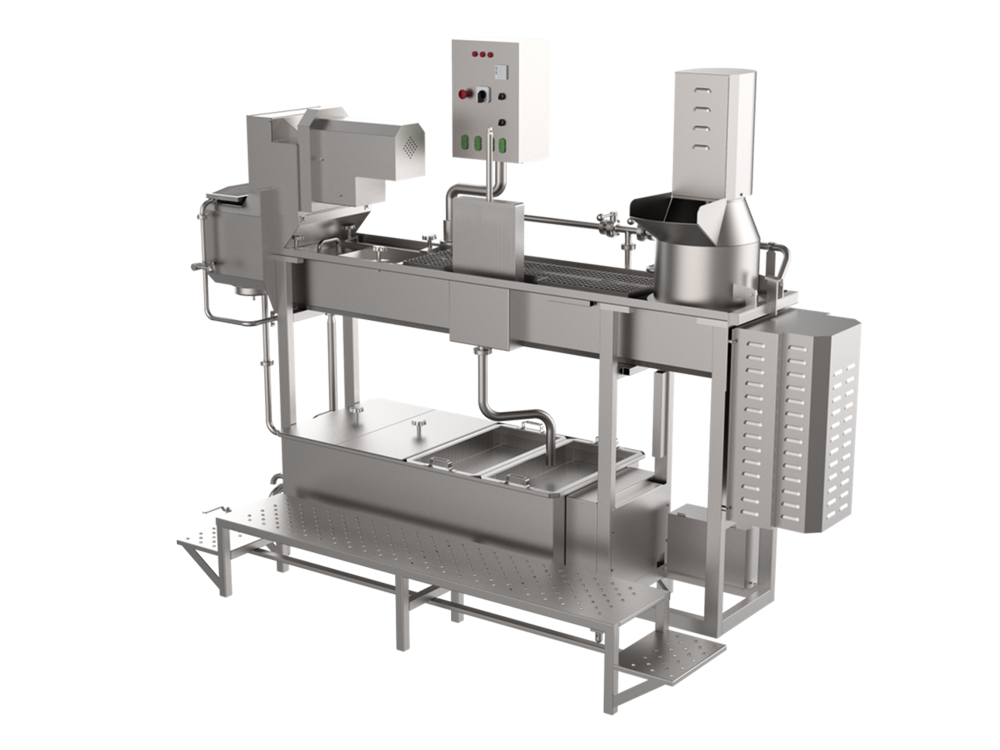

Hard and Semi-Hard Cheese Production Lines

Cooking - Stretching

Working Principle

- Pour the prepared curd into the chopping chamber on the machine.

- The chopped curd is transferred to the boiling machine.

- In the meantime, the water in the chamber passes through the sieve and is poured into the hot water chamber below. The water in the hot water chamber is returned to the scalding chamber with the circulation pump and water is circulated at the same temperature continuously.

- The salt content of the water is constantly measured, and in case of salt deficiency, dry salt is automatically added to the system.

- After the curd reaches the desired degree and consistency, it is transferred to the kneading unit with inverter-adjusted augers.

- In the kneading chamber, the curd is kneaded with a kneading arm until it reaches the desired shape.

- The finished product is transferred to the weighing machine.

Technical Features

- High efficiency due to low water quantity and temperature during stretching.

- Regularity of the water temperature during stretching provided by the temperature sensor on the control panel and the double jacket isolating the processing area.

- Salt conductivity measurement and control system

- PLC controlled

- With speed control unit

- Water level controlled

It allows kneading in two different ways:

-Closed circuit kneading

-Continuous kneading

- Ease of use and control

- Teflon and sandblasting coating,

- Hot water preparation unit.

Application Fields

- Hard, Semi-hard Cheeses

- Mozzarella Cheese

- Cheddar Cheese

Kapasite (Capacity) | Malzeme (Material) | Buhar Sarfiyatı (Steam Consumption) | Elektrik Sarfiyatı (Electric Consumption) | A | B | C |

|---|---|---|---|---|---|---|

| KR - 500 | AISI - 304 & AISI - 316 | 65 kg/h | 3 kw | 1.100 mm | 3.500 mm | 2.100 mm |

| KR - 1000 | AISI - 304 & AISI - 316 | 120 kg/h | 9 kw | 3.000 mm | 5.250 mm | 2.600 mm |

| KR - 1500 | AISI - 304 & AISI - 316 | 150 kg/h | 9,75 kw | 3.000 mm | 5.750 mm | 2.600 mm |