Cream Cheese Production Lines

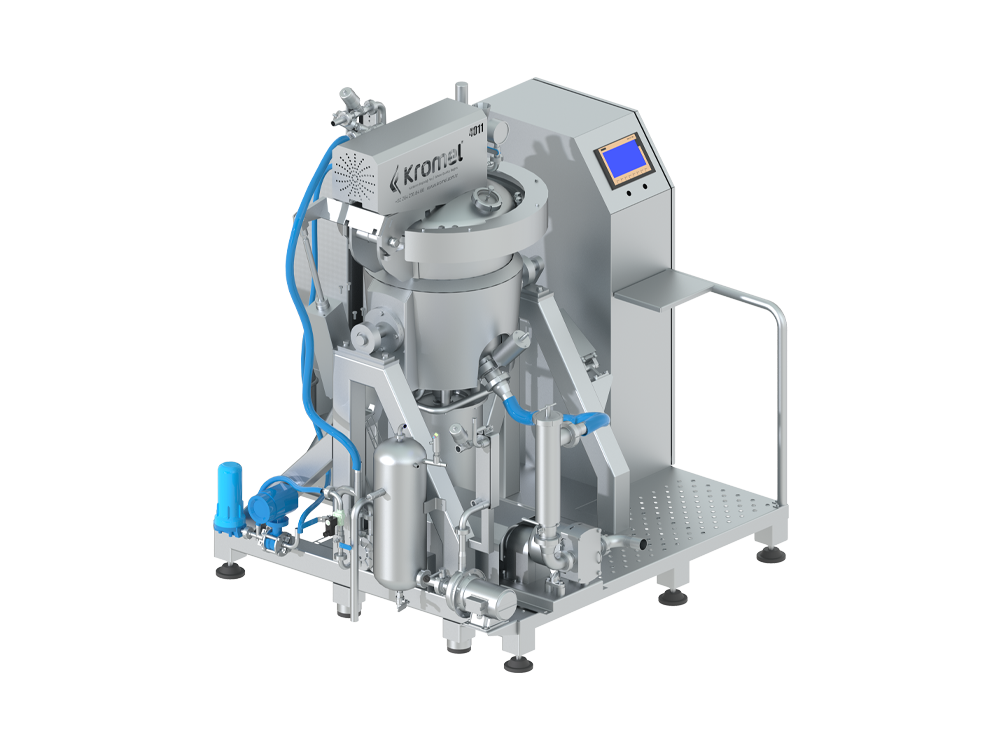

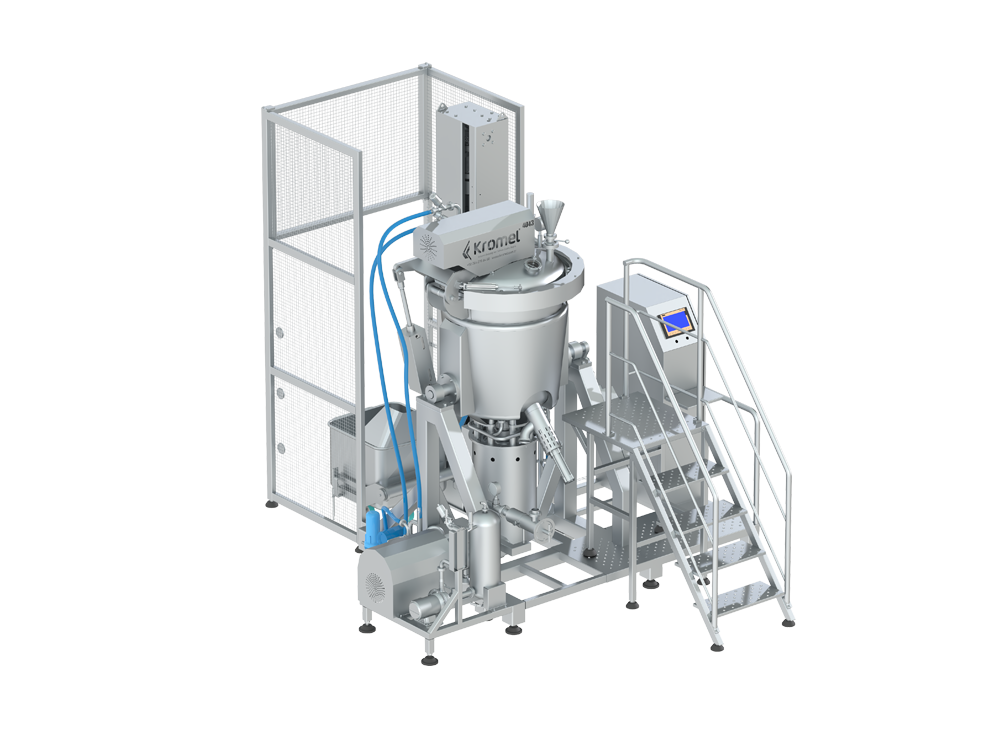

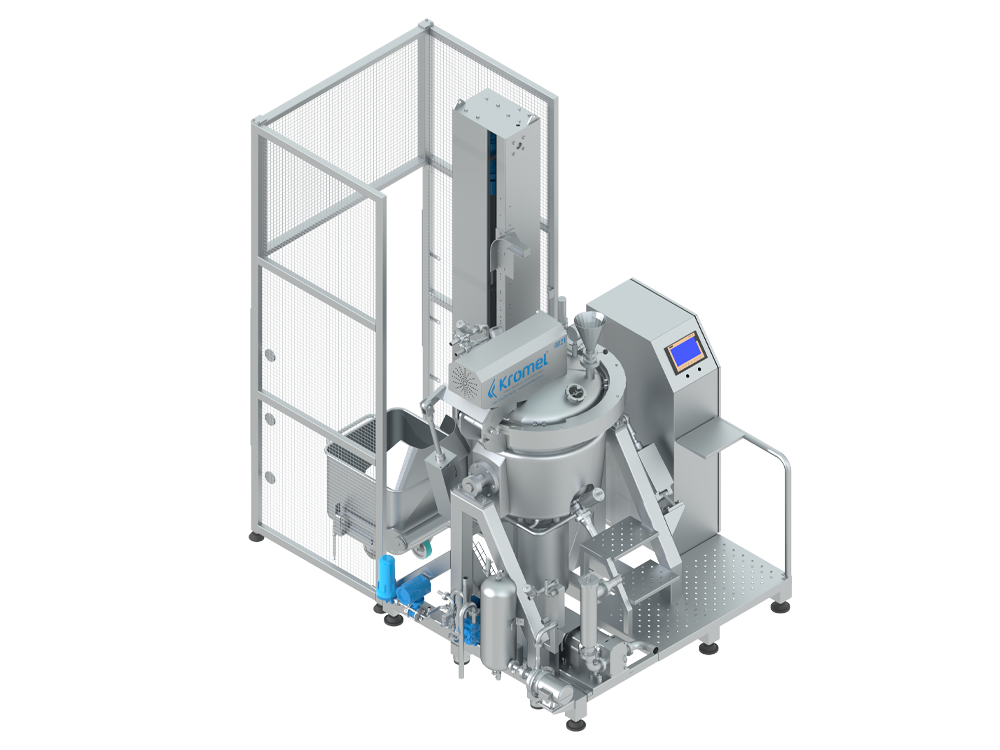

Cookmix

Working Principle

The desired capacity of raw material is put into the machine according to the recipe feature.

Water supply is automatically added into the machine.

Special product inputs are available for other raw material inputs.

Heating process is done by selecting direct or indirect feature.

Bottom mix motor is operated at the desired speed with speed control according to the recipe.

The upper scraper & mixer is opened to ensure effective mixing of the product.

Vacuum process is started according to the recipe.

The prepared product is transferred with the help of automatic valve and product transfer pump.

Technical Features

- Inverter speed controlled bottom mix motor,

- Special two-cutter blade system at the bottom,

- Scraper and mixer reducer on top,

- Direct steam injection Indirect heating and cooling wall

- Vacuum pump

- Automatic product discharge valve

- Steam filter

- Automatic top cover opening system

- Automatic machine tilting system Top cover automatic locking system

- Possibility of automatic operation depending on the prescription recording feature,

System Advantages

- Short processing time

- PLC controlled

- Fast production

- Suitable for cleaning with CIP system,

- Homogeneous mixture

- Alternatives with different loading capacities

- Can be used for many different products

Application Fields

- Melted Cheese

- Cream Cheese

- Analog Cheese

- Hummus

- Ketchup

- Mayonnaise

- Sauces

- Chocolate Sauces