Hard and Semi-Hard Cheese Production Lines

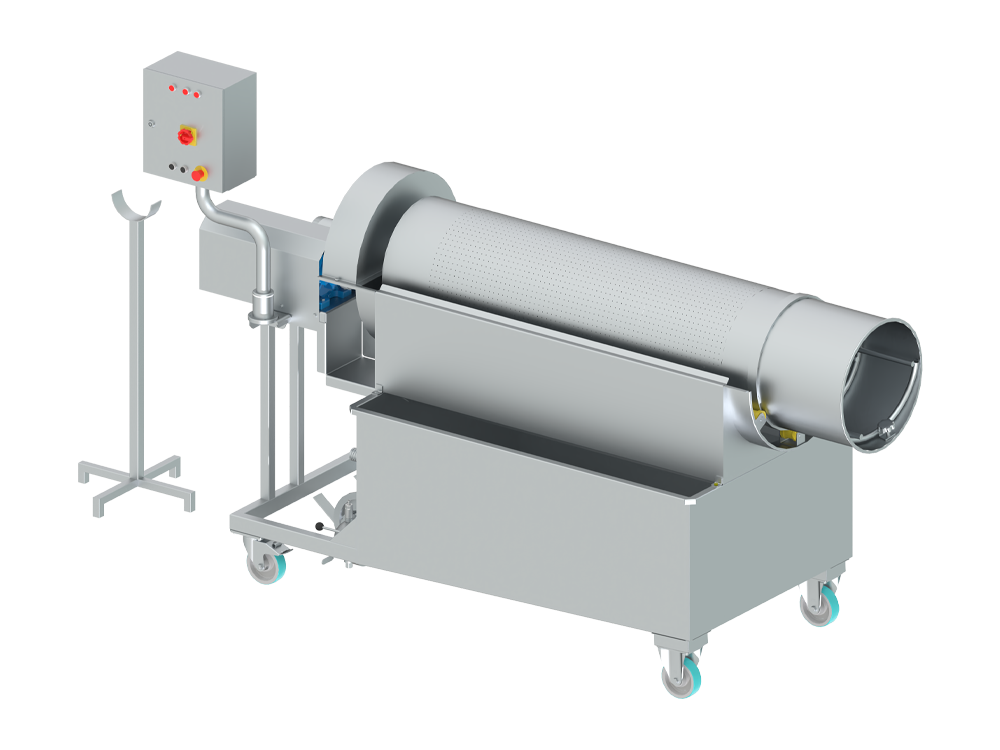

Internal Filtration Drum

Working Srinciple

It is used to separate curd and whey from the product transferred from the process tank by pump or natural flow.

Internal Filtration Drum

- The curd and whey coming to the drum sieve with internal filtration are passed through 1 mm hole diameters.

- Whey is collected in the drum bottom chamber.

- The whey is sent to the desired location via a whey pump under the lower chamber.

- Drum rotation speed can be controlled by inverter.

- The curd is carried forward with the auger in the drum sieve.

- The curd is discharged into the curd trolley or a transport conveyor.

Technical Feature

- It is manufactured from AISI 304 and AISI 316 quality stainless steel sheet.

- Inverter speed controlled.

- There is a prismatic reservoir for curd whey at the bottom of the drum.

- Centrifugal pump is available for transferring whey.

- Suitable for manual and automatic CIP.

Application Fields

- Hard, Semi-hard Cheese Groups

- Cheddar Cheese

- Mozzarella Cheese

- Teleme

System Advantages

- Automatic CIP washing is performed with CIP balls.

- Increase efficiency by preventing drum curd leakage.

- Suitable for filtration of smaller curd.