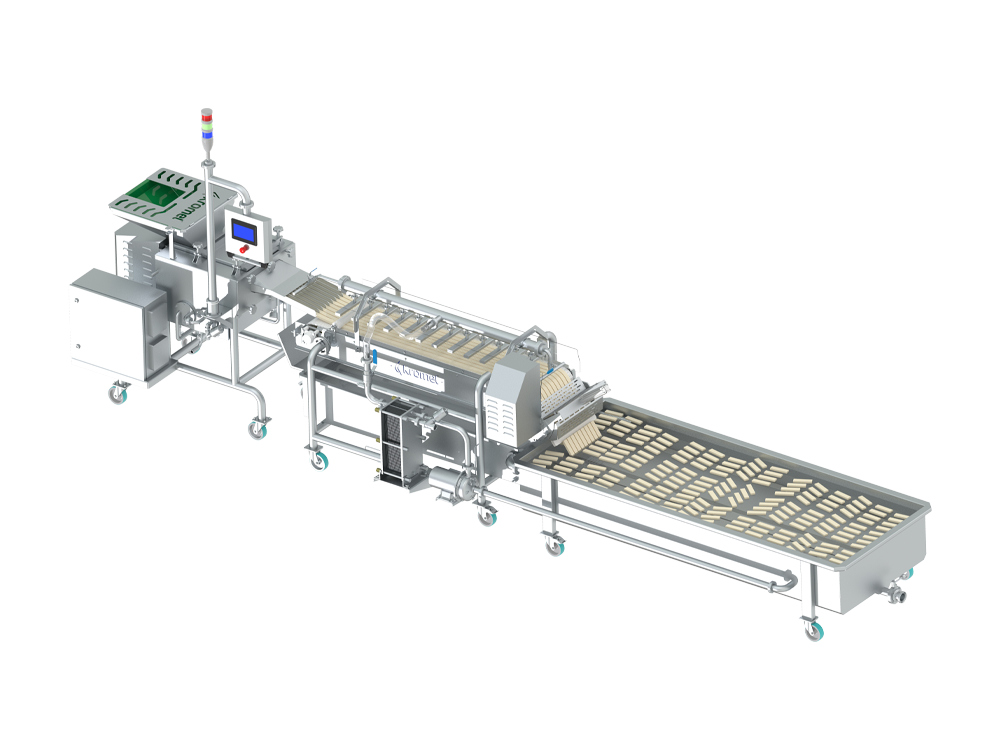

Hard and Semi-Hard Cheese Production Lines

Tongue & Fibrous Forming

Working Principle

- The cheese dough from the kashkaval Streaching machine is sent to the inlet hopper of the tongue & fibrous forming machine.

- The cheese dough coming from the cooking machines is directed towards the form molds by the spirals in the forming machine.

- As the product reaches the molds at the front of the machine, it takes the shape of the molds. The dough passes through the tongue & Fibrous line molds and is hardened with cooling water on the conveyor

- The pneumatic cutter on the conveyor cuts the dough according to the desired size for tongue or fibrous cheese.

- The cut cheese is dropped into a cold water pool via the conveyor.

- The cheese is then removed from the water by the conveyor and is ready for further processing.

Technical Features

- It is completely made of AISI 304 quality material.

- Cooling heat exchanger

- With Circulation Pump

- With speed control unit

- Digitally controlled

- Ability to make products in different capacities

- With cooling pool

- Portioning in desired sizes

- Easy to change molds in different sizes

- Wheeled, portable.

System Advantages

- Fast product processing

- Ability to make standard products

- Production at low cost

- Production at maximum hygiene level

- Weight sensitivity

- Ability to obtain cheese in different shapes with easy mold change.

Application Fields

- Hard, Semi-hard Cheeses

- Tongue Cheese

- Fibrous Cheese

- Mozzarella Cheese

| CAPACITY | ELECTRICITY CONSUMPTION | STEAM CONSUMPTION | AIR CONSUMPTION | ICE WATER CONSUMPTION |

|---|---|---|---|---|

| 350 KG/H | 3 KW | 40 KG/H | 80 LT/DK. (6-8BAR) | 4.000 LT/H (+4°C) |