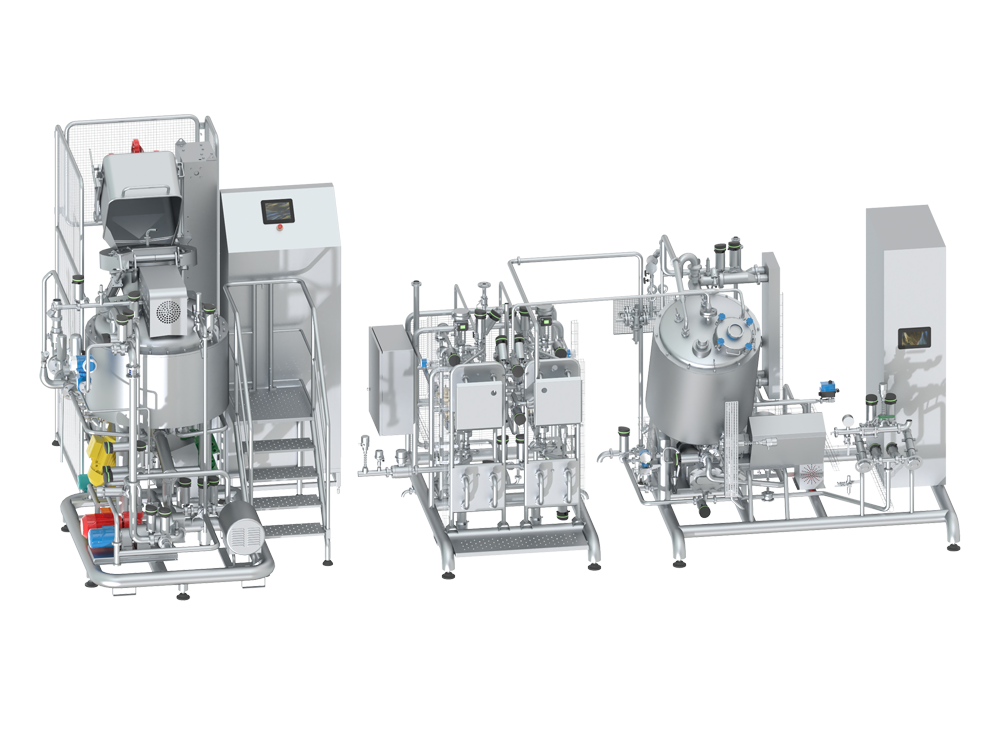

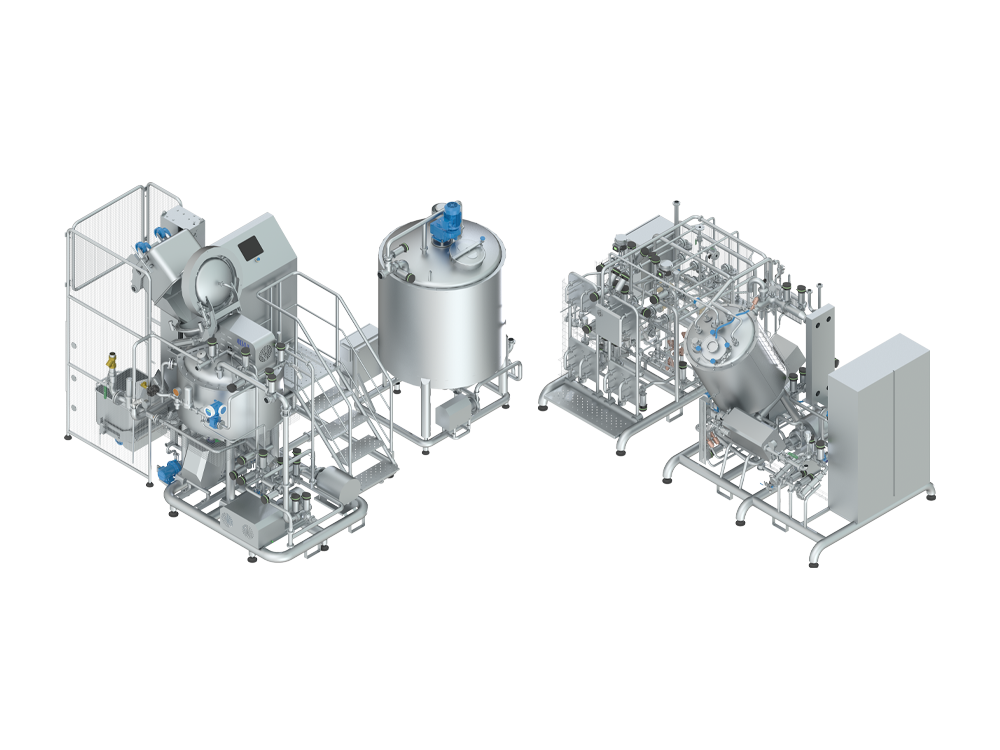

Cream Cheese Production Lines

Ultra High Tempature (UHT) Unit

Working Principle

- The high-tech Kromel brand provid a UHT system which is designed for all types of processed cheese, from low to high viscosity.

- It is designed to extend the shelf life of these cheeses.

- Cheese between 70 and 95 °C is heated to 140 °C and above and kept in the waiting tube for at least 5 seconds.

- The tubes are coated with PTFE (Teflon) material to prevent sticking during the heating process.

- The cheese, which has spent sufficient time in the waiting tube, is cooled to the desired temperature of 85-90 ºC with a controlled vacuum effect.

- In this way, all micro-organisms, bacteria and spores that can damage the product are destroyed. This process extends the shelf life of the product.

Technical Features

- Made of AlSl 304-316 quality stainless steel material.

UHT Unit

- 2-line UHT transition line (1 line product, 1 line cip)

- Balance tank (Optional)

- 2 x Holder (inner surface made of Teflon material)

- 1 x Rapid temperature reduction tank with tubular condenser

- 1 x Creaming tank (Optional)

- 1 x Viscosity control system (Optional)

- 1 x Vapor separation filter (Optional)

- 1 x Tandem filter for the product

- 1 x Steam rising filter (Optional)

- 1 x Steam Separator (Optional)

- 1 x Steam Separator (Optional)

- Siemens PLC System

- Automation and software

- Product line connections available

- Temperature controlled steam heating with control valve system

- Teflon inside and stainless steel outside There are two holders made of material.

- Software to create pressure in the holder section There is a controlled pressure control valve.

- Vacuum pump is available.

- Product pump lobe type pump is used.

- Cip return pump Alfa Laval is used. In-unit piping, cabling and pneumatic installation is available.

- Steam automatic valve diversion system is available.

- Active valves for product automatic diversion system is available.

- ClP cleanup redirection is available.

System Advantages

- High heating capacity with direct steam injection

- Viscosity control system (optional)

- Easy to use Easy maintenance

- Long life system

- CIP cleaning feature

- Production on one line and CIP process on the other line can be done. In case of failure on any line production can easily be resumed on the other line, time and product loss is prevented.

- The system works as a continuous system

- Continuous and uninterrupted operation of the system

- Fully automatic operation

Application Fields

- Srocesset Cheese;

- Spread

- Block

- Slices - Analogue Cheese

- Baby Food

- Hummus